Binders

Feedchem offer a broad range of organic and inorganic

mould and core binder systems.

FEED ALPHA

Alkaline Phenolic Binder

Feed alpha is a high-performance Potassium/Sodium-based alkaline cold setting phenolic binder cured by Ester. This process offers numerous advantages over existing binder systems. They can be successfully used with a wide range of metals and alloys.

Benefits

- Significantly improved levels of mechanical reclamation in both ferrous and Non-ferrous foundries

- Low hardener consumption

- Low levels of monomer evolution during mould production, casting and shakeout

- Overall Good environmental properties

- Excellent mould and core strength

- High temperature plasticity

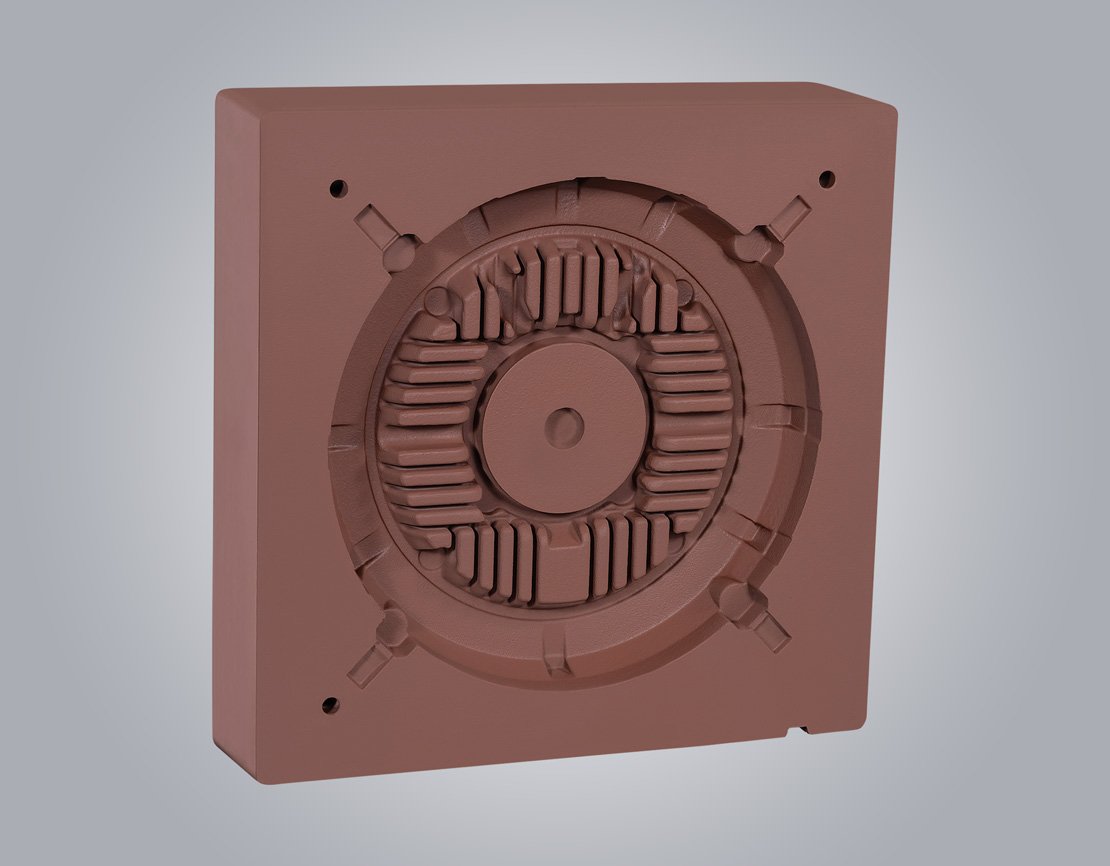

Application

Production of Cores and moulds, especially for Steel Castings.

Hardener of Feed Alpha (Ester)

Catalyst for Feed alpha is a colourless liquid. The process uses a binder system which is cured by the use of a liquid organic ester hardener. The hardener product range of Feed Alpha ensures optimized addition & superior mixed sand bench life to curing time ratios.

FEED COLD

Cold Box System

Feedcold is a benzylic ether type synthetic binder for coldbox process. It is remarkable for its high thermal stability and extreme long bench life (2hr-3hr) of the sand mixture. It is characterized by very low sticking tendency and low moisture sensitivity. This is a three-part system with hardliner and liquid amine catalysts which cures the binder.

Benefits

- High Productivity – Large volume high speed production

- No tooling heat required, Cures at room temperature

- Cost effective to run in comparison to heat cured systems

- Good dimensional accuracy, very good flow ability of sand mix

- Cores can be handled immediately

- Cores can be cast as early as possible

- Shelf life of resin is long

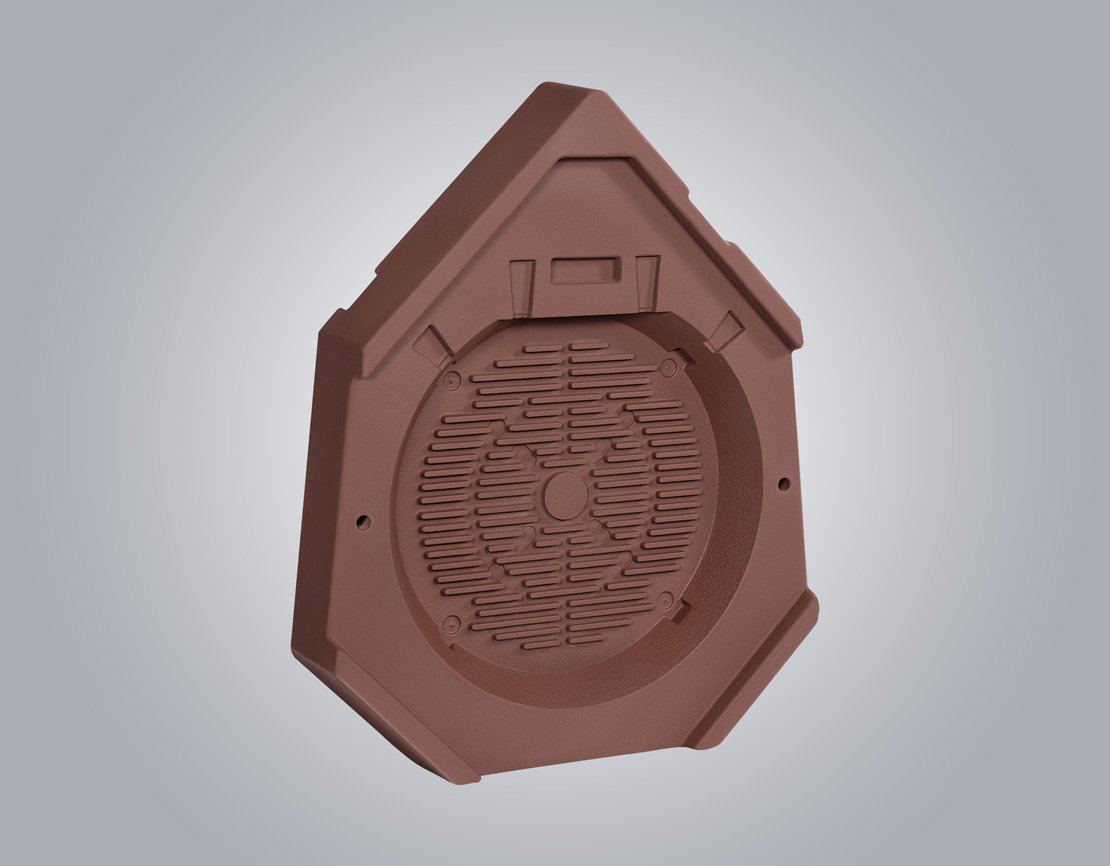

Application

The cold box process is mainly used in casting of cores for automotive castings due to its excellent dimensional accuracy. Cores for iron castings can be made. They are suited for high productivity as well as for large cores which require rapid strength increase.

FEED PHENOL

Phenolic Binder Cured with Acid

Feed phenol is a cold curing Nitrogen free liquid phenolic formaldehyde resole resin. This resin is used for production of core’s and moulds for grey cast iron, ductile iron, cast steel and non ferrous heavy metal.

Benefits

- This product is Nitrogen free

- Basic raw materials are indigenous

- Initial handling strength is good

- Reclaim ability is good

- Improved casting quality

- Low Sand to Metal Ratio

- Baking is not required, thus baking ovens are eliminated

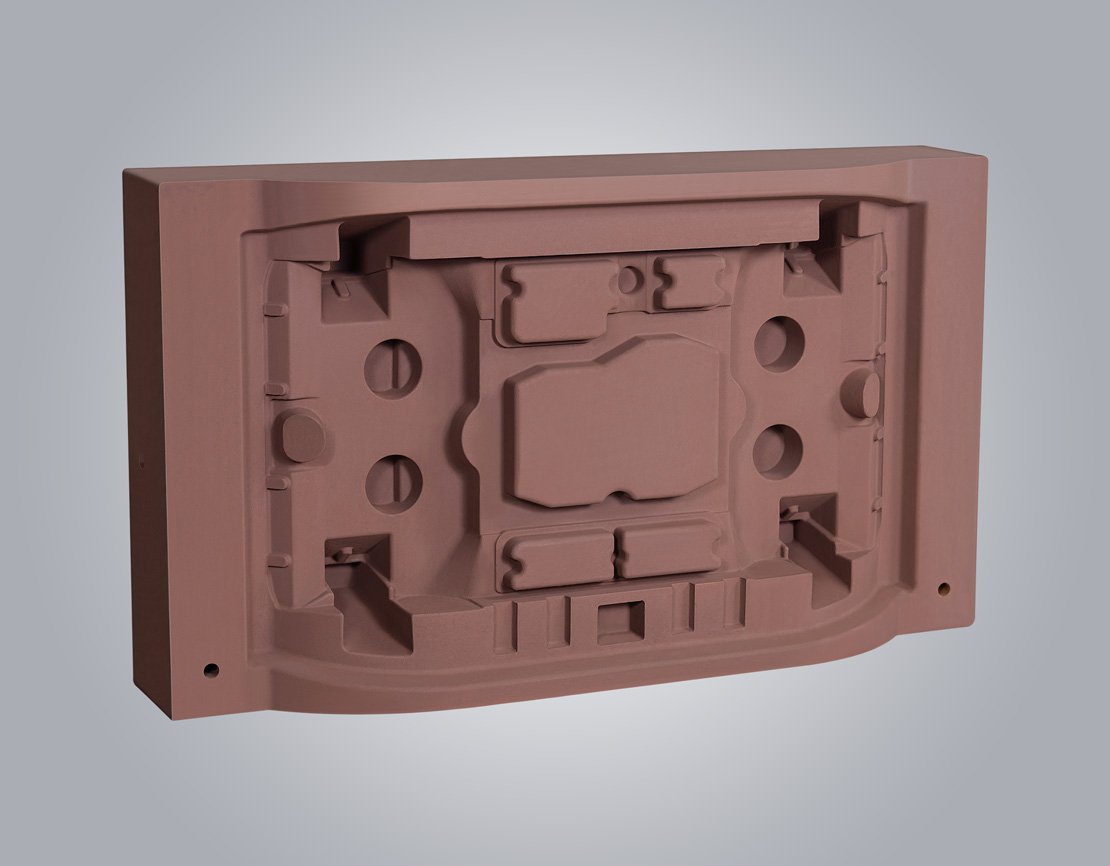

Application

Production of cores and moulds for grey cast iron, ductile iron, cast steel and non ferrous heavy metals.

FEED FUR

Furan Binder Cured By Acid

Feed fur is an acid cured Furan No Bake Binder System. It is especially designed and manufactured to meet requirement of Indian foundries with Indian sands. The product is suitable for making smaller/larger cores or moulds using continuous mixer/using conventional sand mixer. It has flexibility to accommodate use of reclaimed sand upto 90%. This system gives excellent hot strength and eliminates metal penetration and sand expansion defects.

Benefits

- Improved casting quality

- Low Sand to Metal Ratio

- Low pattern Wear as sand mixes are very free flowing

- Baking is not required, thus baking ovens are eliminated

- Excellent resistance to penetration

- Greatly reduces cleaning cost

- No wall movement, reduces pin holes specially in steel & SG iron castings

- Low viscosity of Binder allow sand to flow freely and good compaction is achieved

- No special storing condition. Low storage life due to more stability, particularly suitable for hot climate

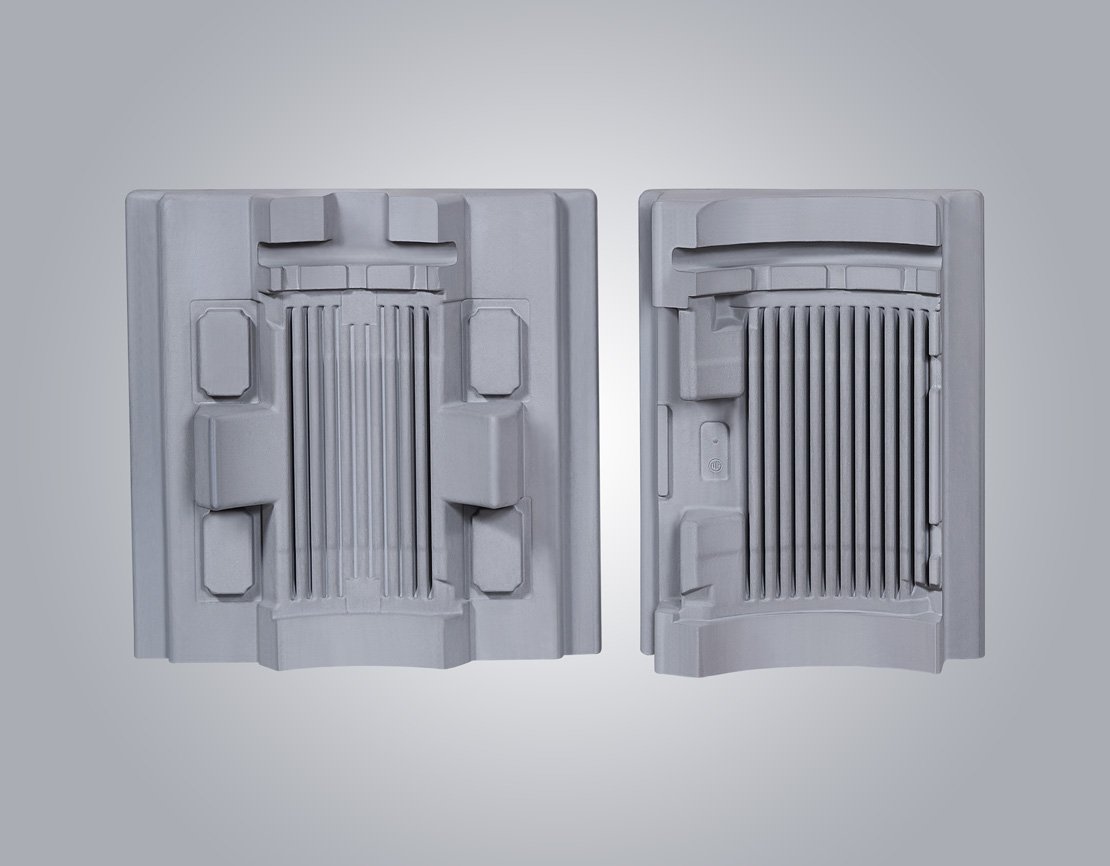

Application

It is excellent for making large steel castings where high hot strength and low gas is required.

FEEDHARD

Catalyst for Feed phenol & Feed Fur

Feed hard is made by using PTSA, xylene sulphonic acid and lactic acid to activate the polymerisation process when mixed with binders. Bench life can be controlled from 3 minutes onwards depending upon the climatic conditions as well as the proper selection of binders and hardeners.

Single Part Binder

Air Set

Feed Set is used to make moulds and cores in Foundry

Benefits

- Any grade(washed/unwashed) of Silica sand can be used

- Very good surface finish of casting can be achieved

- Good mould release

Application

It is excellent for making open core mould boxes.